What is a CNC Machine?

ChinaCNCzone

2017-03-28 16:49:55

Computer numerical control is automatic machine with a program control system. This system can deal with program which include control code or others instructions defining symbol and translate them to let the machine work. It abbreviate to CNC.

Features:

Below is CNC features, compared with general machine.

1. High working precision, with stable producing quality.

2. Multi-axis simultaneous control can process intricately shaped parts.

3. Just change the program control can meet different part processing work.

4. Higher productivity than general machine, about 3-5 times.

5. High automatization means labor saving.

6. Both operator and maintenance personnel should be professional.

Working principle

Almost CNC machine includes below parts,

1. Main body, it is the subject of CNC machine, include bed, upright, spindle, feeding machanism etc, it is the part to finish all cutting and engraving process.

2. Numerical control device, the core of CNC machine, includes hardware (PCB broad, CRT display ect) and relevant software, its function is to control numerical program inputting, data storage, data conversion and interpolation calculation.

3. Diving device, it is the drive element including spindle drive unit, feeding drive unit, spindle motor and feeding motors. It make spindle and feeding drive unit work by electric or electro-hydraulic servo system under the control of numerical control device.

4. Auxiliary device, it refers to some necessary matching accessories to ensure the operating of CNC machine, like cooling, chip removing, lubrication, lighting and monitoring etc. It includes hydraumatic and air-operated device, chip removing device and pallet changer, NC rotary table, NC dividing head, tools and monitoring device.

5. Programming and others additional device for program and storage.

Usage:

CNC machine mainly used in large-scale parts processing, can be used in quantity production and high automatic production.

Since 1952 MIT developed the first CNC machine, it has been widely using in producing industry, specially in automobile industry, space and aeronautics industry and military industry. Both in hardware and software, CNC machine has a fast development.

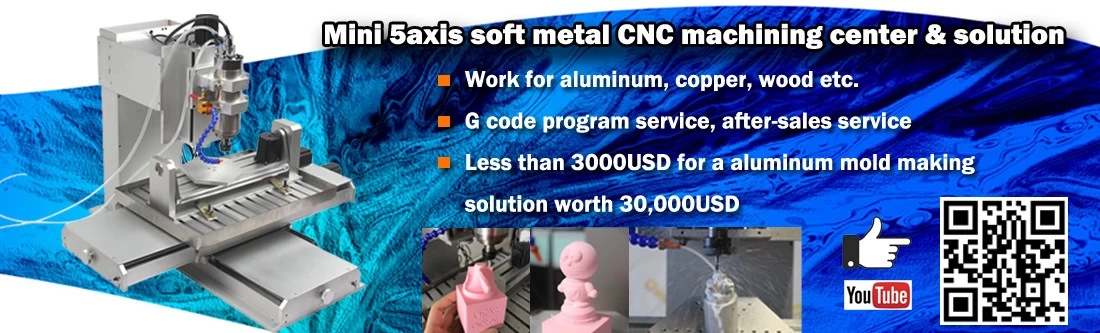

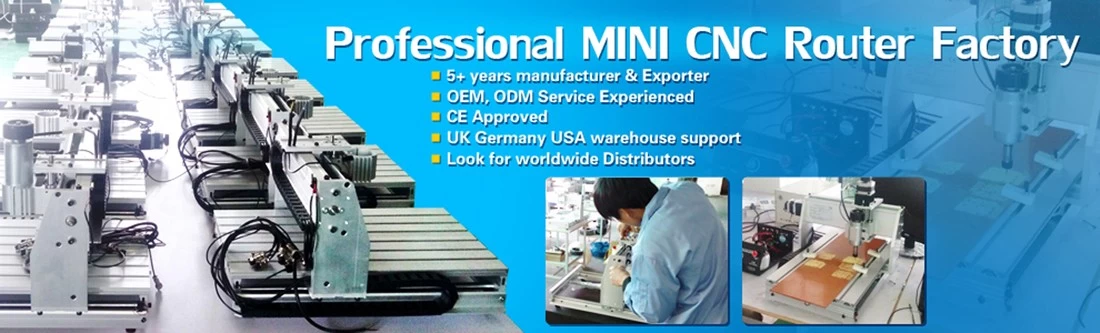

For quite a long time, the CNC machines on the market are bigger size and heavy weight, many customer needs small size one, so ChinaCNCzone established. It focus on China mini CNC router manufacturing, its hot models are CNC 3040, CNC 6040,CNC 6090, HY 3040 and HY-6040 serials through years of development, now it is the leading manufacturer and supplier for China cnc routers and CO2 laser engraving machine,and fiber laser marking machine..

Features:

Below is CNC features, compared with general machine.

1. High working precision, with stable producing quality.

2. Multi-axis simultaneous control can process intricately shaped parts.

3. Just change the program control can meet different part processing work.

4. Higher productivity than general machine, about 3-5 times.

5. High automatization means labor saving.

6. Both operator and maintenance personnel should be professional.

Working principle

Almost CNC machine includes below parts,

1. Main body, it is the subject of CNC machine, include bed, upright, spindle, feeding machanism etc, it is the part to finish all cutting and engraving process.

2. Numerical control device, the core of CNC machine, includes hardware (PCB broad, CRT display ect) and relevant software, its function is to control numerical program inputting, data storage, data conversion and interpolation calculation.

3. Diving device, it is the drive element including spindle drive unit, feeding drive unit, spindle motor and feeding motors. It make spindle and feeding drive unit work by electric or electro-hydraulic servo system under the control of numerical control device.

4. Auxiliary device, it refers to some necessary matching accessories to ensure the operating of CNC machine, like cooling, chip removing, lubrication, lighting and monitoring etc. It includes hydraumatic and air-operated device, chip removing device and pallet changer, NC rotary table, NC dividing head, tools and monitoring device.

5. Programming and others additional device for program and storage.

Usage:

CNC machine mainly used in large-scale parts processing, can be used in quantity production and high automatic production.

Since 1952 MIT developed the first CNC machine, it has been widely using in producing industry, specially in automobile industry, space and aeronautics industry and military industry. Both in hardware and software, CNC machine has a fast development.

For quite a long time, the CNC machines on the market are bigger size and heavy weight, many customer needs small size one, so ChinaCNCzone established. It focus on China mini CNC router manufacturing, its hot models are CNC 3040, CNC 6040,CNC 6090, HY 3040 and HY-6040 serials through years of development, now it is the leading manufacturer and supplier for China cnc routers and CO2 laser engraving machine,and fiber laser marking machine..