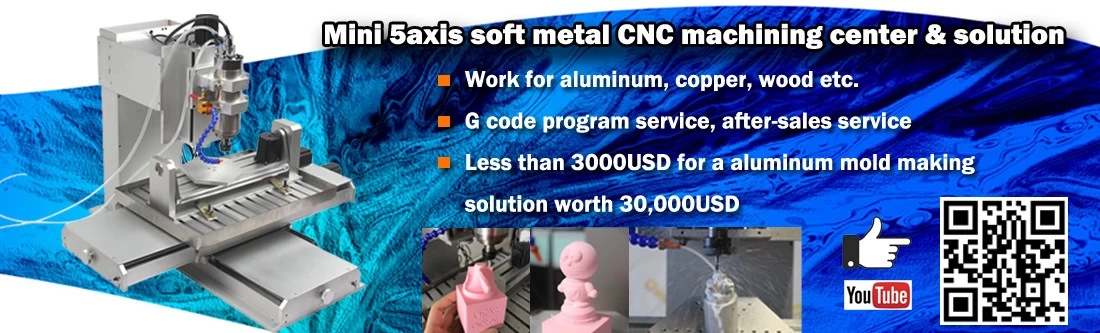

2020 Cnc Router cutting aluminium for Complex model parts

On March 27, 2020, our company conducted a aluminum model parts engraving.

The following are more details.

Step 1. Preparation

(1) Below is our aluminum block material before engraving:

(2) Below are our engraving bits:

4mm 4 fluts end mill

Step 2. Process:

These are our experimental procedures, which mainly include three aspects: rough engraving by 6mm 4 fluts end mill ,accuracy engraving by 4mm R2 end mill and 6mm 4 fluts end mill

(1)Rough Engraving by 6mm 4 fluts end mill

Table 1 .Rough Engraving by 6mm 4 fluts end mill Parameter Table

|

Project |

Value |

|

Carving Tool |

6mm 4 fluts end mill |

|

Spindle Speed |

10000RPM |

|

Feed Speed |

800mm/min |

|

Feed Depth |

0.15mm |

|

Precision |

0.02mm |

|

Processing Time |

40mins |

(2)Accuracy Engraving by 4mm R2 end mill

This is the first step of accuracy Engraving

Table 2 .Accuracy Engraving by 4mm R2 end mill Parameter Table

|

Project |

Value |

|

Carving Tool |

4mm R2 end mill |

|

Spindle Speed |

10000RPM |

|

Feed Speed |

500mm/min |

|

Feed Depth |

0.1mm |

|

Precision |

0.02mm |

|

Processing Time |

60mins |

(3)Accuracy Engraving by 6mm 4 fluts end mill

This is the final step of accuracy Engraving

Table 3 .Rough Engraving by 6mm 4 fluts end mill

|

Project |

Value |

|

Carving Tool |

6mm 4 fluts end mill |

|

Spindle Speed |

13000RPM |

|

Feed Speed |

1100mm/min |

|

Feed Depth |

0.15mm |

|

Precision |

0.02mm |

|

Processing Time |

1mins |

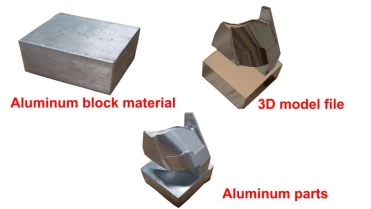

Step 3. Product comparison before and after engraving

Below,The two figures above are the jade material and 3d file picture, The following picture is aluminum model parts sample after engraving.

More exciting videos, please click youtube linkMore exciting videos, please click youtube link:https://www.youtube.com/watch?v=e1ZbFDZq7KQ

Chinacnczone wish you all the best.