Stone cnc router machine for jade with Steel Structure and Linear Guide carved Dragon And Phoenix

Step 1. Preparation

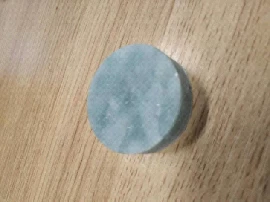

(1) Belowis our jade Material before engraving:

(2) Belowis our engraving bit(P45-0.2 Full Width 45°、0.2Tip):

(3) Belowis the stone machine used in our engraving process:

Step 2. Process:

These are our experimentalprocedures, which mainly include two aspects: rough engraving and acurracyengraving

(1)Rough Engraving

Our engineers use fixtures tofix the jade material and then rough it.

Table 1 .Rough EngravingParameter Table

|

Project |

Value |

|

Carving Tool |

PCD P45-0.2(Full width 45°、0.2Tip) |

|

Spindle Speed |

20000RPM |

|

Feed Speed |

600mm/min |

|

Feed Depth |

1.5mm |

|

Precision |

0.03mm |

|

Processing Time |

30mins(0.5h) |

(2)Acurracy Engraving

When the rough engraving iscompleted, let's finish the acurracy engraving.

Table 2. Acurracy EngravingParameter Table

|

Project |

Value |

|

Carving Tool |

PCD P45-0.2(Full width 45°、0.2Tip) |

|

Spindle Speed |

20000RPM |

|

Feed Speed |

600mm/min |

|

Feed Depth |

1.5mm |

|

Precision |

0.03mm |

|

Processing Time |

180mins(3h) |

Step 3. Product comparison before andafter engraving

Below,the left picture is thejade material before engraving, The right picture is the dragon and phoenixafter engraving.

Step 4.Process Aspects That Can BeImproved

If you want better precision,you can improve machining accuracy by changing machining parameters andextending machining time.

Chinacnczone wish youall the best.