steel structure small cnc 3d carving wood model milling wood planer machine

On May 15, 2020, our company conducted a wood model engraving. The following are more details.

Step 1. Preparation

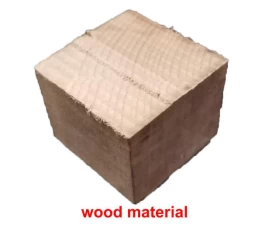

(1) Below is our steel stainless material before engraving:

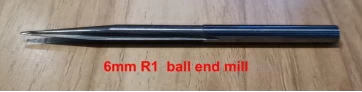

(2) Below is our engraving bits:

Step 2. Process:

These are our experimental procedures, which mainly include two aspects: rough engraving by 6mm R1 ball end mill ,accuracy engraving by 6mm R1 ball end mill

(1)Rough Engraving by 6mm R1 ball end mill

Table 1 .Rough Engraving by 6mm R1 ball end mill Parameter Table

|

Project |

Value |

|

Carving Tool |

6mm R1 ball end mill |

|

Spindle Speed |

11000RPM |

|

Feed Speed |

1000mm/min |

|

Feed Depth |

0.15mm |

|

Precision |

0.02mm |

|

Processing Time |

10mins |

(2)Accuracy Engraving by 6mm R1 ball end mill

This is the step of accuracy Engraving

Table 2 .Accuracy Engraving by 6mm R1 ball end mill Parameter Table

|

Project |

Value |

|

Carving Tool |

6mm R1 ball end mill |

|

Spindle Speed |

10000RPM |

|

Feed Speed |

500mm/min |

|

Feed Depth |

0.05mm |

|

Precision |

0.02mm |

|

Processing Time |

20mins |

Step 3. Product comparison before and after engraving

Below,The two figures above are the wood material and wood model, The following picture is wood model sample after engraving.

Chinacnczone wish you all the best.