Efficient processing strategy during UG programming processing, enhance actual combat experience!

In fact, by looking at the knife path you have taken, you will know the level you are currently at; aren’t many things classified into levels now? Once you have a level, then you know what to do.

Generally speaking, the way of knife moves reveals the level of your knife. Good skills and laziness are a way of movement; good skills and diligence are a way of movement; poor skills are lazy. Yes, it is a way of walking; those with poor technique and diligence are a way of walking. Which do you belong to?

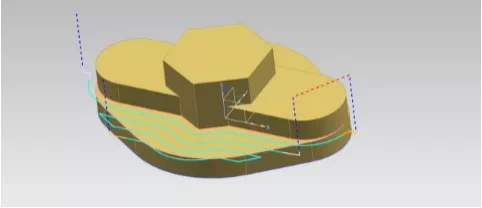

How to process the surface with the red circle on the part in the above picture?

I will talk about this issue today.

First of all, the design of this part is problematic. There are 4 corners that cannot be machined theoretically.

We call the highest surface A, the four-hole racetrack-shaped surface B, and the bottom C.

This unprocessed corner is where B and C stand linking.

Generally speaking, since it can't be processed, the area will not be processed after roughing, because you can't process it "clean" anyway.

Lazy people, who want to seek safety, can use slot milling, and face milling is all right.

Different people have different paths in the end. Because there are many parameters in a toolpath. We presume to finish

How to judge the quality of this pass?

There are several criteria, one is the efficiency of the knife, how much is the knife lifted? Someone immediately said, how can we not carry the knife? This question is also complicated, and it cannot be said clearly in a sentence. It can only be said that you try to carry the knife as little as possible, not to prevent you from lifting the knife. This is about your economic benefits.

The other is whether the knife makes a loud noise at the corner, that is, do you avoid the air? Just this one issue can be discussed for a long time, and this will be discussed later. This problem is related to the life of the tool and the deformation of the machine tool spindle.

The other is whether there are areas where the processing is required to be processed, and areas with high accuracy must be processed with high accuracy. That is, did you follow the processing requirements. Some people say that since I took the knife, no one has ever given me this request. That is, the working environment of each face on the workpiece determines how the face will face the customer who bought it in the future. If you say this, it feels like a heavenly book. If there are 100 faces and 1000 faces on a workpiece, then there should be 1000 requirements, but there are N requirements at the end. This N is generally less than 10. For a curved surface without any surface finish, if you ask for a flatness of 0.003, the boss would be a disaster for him to hire you. This is about your cost.